When Shell UK identified the need to carry out a Magnetic Anisotropic and Permeability System – Flexible Riser (MAPS-FR) inspection to verify the condition of ageing assets in the UK continental shelf, it turned to JF Subtech specialist subsea support for a safe and cost-effective solution.

The Curlew field is located in the Central North Sea, 210 km east of Aberdeen, at a water depth of approximately 92 metres. The field consists of reservoirs connected via flexible lines to a Floating, Production, Storage and Offloading (FPSO) unit, Curlew.

Project completed: 2017

The challenge

- The Curlew Gas Export Riser is a flexible riser operated for export quality gas service, installed in 1997 with a 15-year design life.

- Shell UK wanted to carry out a life extension assessment, performed in line with company policy.

- MAPS-FR can detect broken wires within +/- 15m of the scanned location in flexible pipe and has been successfully deployed many times using divers, but this required the system to be capable of being deployed by an Inspection Class Remotely Operated Vehicle (ROV) due to the location of the bend stiffener. Shallow diving was the other option, but would increase HSSE risk and costs.

- There were several challenges, which included: developing a concept for the ROV and MAPS inspection to be integrated, operating in a shallow water depth environment and testing in tank water conditions and application offshore.

- This would require the development and testing of a new subsea deployment system for use with a ROV.

The solution

- The MAPS-FR ROV scanner employed both hydraulic and electrical actuation, with on-board automated, backup systems to allow easy retrieval from the riser in the event of a ROV power or communication failure.

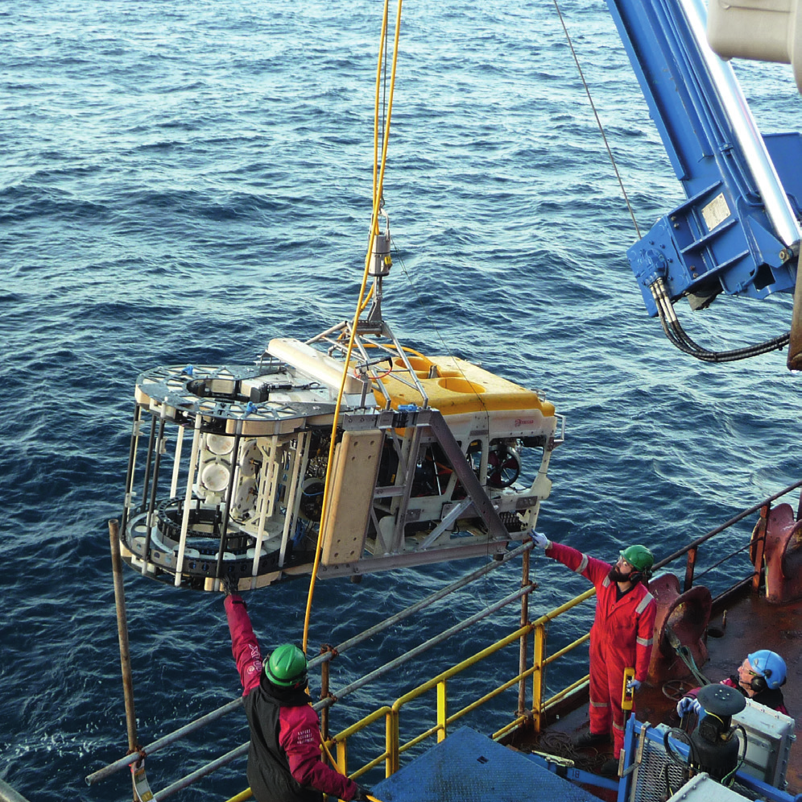

- The scanner was mated to a Saab Seaeye Cougar XT ROV operated by JF Subtech and successfully tested in an onshore tank.

- Four key objectives were identified for the tests:

- To integrate the ROV and scanner and witness that all systems were working.

- To confirm that the scanner/frame could be lifted by the launch and recovery system.

- To confirm that the ROV/scanner could fly in the water satisfactorily and could attach /detach to/from the riser.

- To confirm that the scanner could move around the riser and that all four probes could gather data.

The results and benefits

- JF Subtech safely completed the world’s first MAPS-FR ROVD scan in September 2017, on budget with minimal impact to operations.

- This was a key activity to support the life extension of this dynamic flexible riser which was achieved using an innovative, tailored solution.

- Conventionally these type of inspections are carried out using divers. To remove this need, and any potential hazards involved, JF Subtech provided a gravity-based ABROV system which kept costs to a minimum.